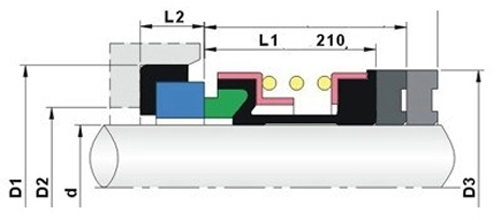

| N210 SEALS By SIZE INCH | d | D | D1 | L1 | L2 |

|---|---|---|---|---|---|

| -3/8" | 9.525 | 20 | 22.22 | 7.9 | 15.2 |

| -1/2" | 12.7 | 24 | 25.4 | 7.9 | 15.2 |

| -5/8" | 15.875 | 26 | 31.75 | 10.3 | 15.2 |

| -3/4" | 19.05 | 32 | 34.93 | 10.3 | 20. |

| -7/8" | 22.225 | 36 | 38.1 | 10.3 | 20.2 |

| 1" | 25.4 | 39 | 41.28 | 11.1 | 20.2 |

| -1 1/8" | 28.575 | 42 | 44.45 | 11.1 | 26.2 |

| -1 1/4" | 31.75 | 46 | 47.63 | 11.1 | 26.2 |

| -1 3/8" | 34.925 | 49 | 50.8 | 11.1 | 26.2 |

| -1 1/2" | 38.1 | 54 | 53.98 | 11.1 | 30.2 |

| -1 3/4" | 44.45 | 61 | 63.5 | 12.7 | 30.2 |

| -1 7/8" | 47.625 | 64 | 66.68 | 12.7 | 30.2 |

| -2" | 50.8 | 66 | 69.85 | 12.7 | 30.2 |

| -2 1/8" | 53.975 | 69 | 76.2 | 14.3 | 30.2 |

| -2 1/4" | 57.15 | 77 | 79.38 | 14.3 | 33.2 |

| -2 3/8" | 60.325 | 80 | 82.55 | 14.3 | 33.2 |

| -2 1/2" | 63.5 | 83 | 85.73 | 14.3 | 33.2 |

| -2 5/8" | 66.675 | 88 | 85.73 | 15.9 | 33.2 |

| -2 3/4" | 69.85 | 89 | 88.9 | 15.9 | 33.2 |

| -2 7/8" | 73.025 | 96 | 95.25 | 15.9 | 33.2 |

| -3" | 76.2 | 99 | 98.425 | 15.9 | 40.2 |

| -3 1/8" | 79.375 | 103 | 101.6 | 19.8 | 40.2 |

| -3 1/4" | 82.55 | 104 | 104.775 | 19.8 | 40.2 |

| -3 3/8" | 85.725 | 108 | 107.95 | 19.8 | 40.2 |

| -3 5/8" | 92.075 | 114.3 | 19.8 | 40.2 | 15.2 |

| -3 3/4" | 95.25 | 118 | 117.475 | 19.8 | 40.2 |

| -3 7/8" | 98.425 | 122 | 120.65 | 19.8 | 40.2 |

| -4" | 101.6 | 124 | 123.83 | 19.8 | 40.2 |

N210 MECHANICAL SEAL