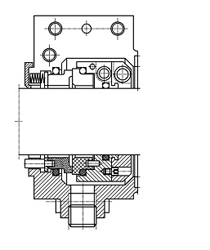

| N-SPLIT(M M) |

|---|

| D | D | d1 | d2 | da | a | s | I1 | I2 | I3 | I4 | I5 | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 | 1.969 | 75 | 84 | 138 | 88 | 15 | 63 | 61 | 30 | 45 | 3 | 3/8'' |

| 60 | 2.362 | 89 | 101 | 149 | 105 | 17.5 | 64 | 62 | 30 | 46 | 3 | 3/8'' |

| 70 | 2.756 | 98 | 113 | 176 | 118 | 20 | 64 | 62 | 30 | 46 | 3 | 3/8'' |

| 80 | 3.150 | 110 | 132 | 191 | 135 | 20 | 65 | 63 | 31 | 47 | 3 | 3/8'' |

| 90 | 3.543 | 121 | 140 | 203 | 145 | 22 | 72.5 | 70.5 | 31.5 | 50.5 | 3 | 1/2'' |

| 100 | 3.937 | 131 | 150 | 216 | 155 | 22 | 72.5 | 70.5 | 31.5 | 50.5 | 3 | 1/2'' |

| 110 | 4.331 | 142 | 165 | 230 | 170 | 22 | 72.5 | 70.5 | 31.5 | 50.5 | 3 | 1/2'' |

| 120 | 4.724 | 152 | 175 | 240 | 180 | 22 | 72.5 | 70.5 | 31.5 | 50.5 | 3 | 1/2'' |

| 125 | 4.921 | 162 | 185 | 268 | 190 | 26 | 89.5 | 87.5 | 43.5 | 62.5 | 4 | 1/2'' |

| 140 | 5.512 | 175 | 200 | 303 | 205 | 26 | 89.5 | 87.5 | 43.5 | 62 | 4 | 1/2'' |

| 150 | 5.906 | 188 | 215 | 308 | 220 | 26 | 89.5 | 87.5 | 43.5 | 62.5 | 4 | 1/2'' |

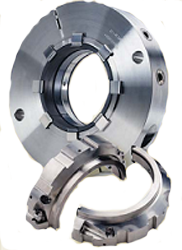

NSPLIT SEAL