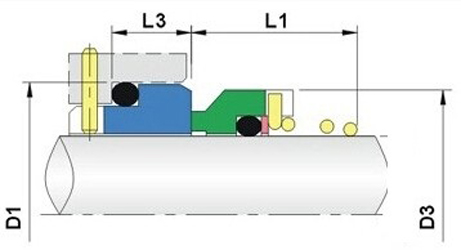

| NM2N SEALS By SIZE | d | D | D1 | L1 | L2 |

|---|---|---|---|---|---|

| -8 | 8 | 16 | 17.1 | 5.5 | 15.2 |

| -10 | 10 | 17.5 | 18.1 | 5.5 | 15.2 |

| -12 | 12 | 20 | 20.6 | 5.5 | 18.2 |

| -14 | 14 | 23 | 23.1 | 6 | 22.2 |

| -15 | 15 | 24 | 26.9 | 7 | 22.2 |

| -16 | 16 | 26 | 26.9 | 7 | 23.2 |

| -17 | 17 | 27 | 26.9 | 7 | 23.2 |

| -18 | 18 | 29 | 30.9 | 8 | 24.2 |

| -19 | 19 | 30 | 30.9 | 8 | 25.2 |

| -20 | 20 | 30 | 30.9 | 8 | 25.2 |

| -22 | 22 | 34 | 35.4 | 8 | 25.2 |

| -24 | 24 | 35 | 35.4 | 8 | 27.2 |

| -25 | 25 | 37 | 38.2 | 8.5 | 27.2 |

| -26 | 26 | 38 | 38.2 | 8.5 | 27.2 |

| -28 | 28 | 42 | 43.3 | 9 | 29.2 |

| -30 | 30 | 43 | 43.3 | 9 | 30.2 |

| -32 | 32 | 45 | 43.3 | 9 | 30.2 |

| -33 | 33 | 48 | 53.5 | 11.5 | 39.2 |

| -35 | 35 | 50 | 53.5 | 11.5 | 39.2 |

| -38 | 38 | 54 | 60.5 | 11.5 | 39.2 |

| -40 | 40 | 56 | 60.5 | 11.5 | 39.2 |

| -42 | 42 | 59 | 60.5 | 11.5 | 39.2 |

| -43 | 43 | 60 | 60.5 | 11.5 | 39.2 |

| -45 | 45 | 64 | 65.5 | 11.5 | 41.2 |

| -48 | 48 | 68 | 65.5 | 11.5 | 41.2 |

| -50 | 50 | 69 | 72.5 | 11.5 | 45.2 |

| -55 | 55 | 74 | 72.5 | 11.5 | 47.2 |

| -60 | 60 | 80 | 79.3 | 11.5 | 49.2 |

| -65 | 65 | 87 | 84.5 | 11.5 | 51.2 |

| -70 | 70 | 92 | 89.5 | 11.5 | 51.2 |

| -75 | 75 | 97 | 94.5 | 11.5 | 57.2 |

| -80 | 80 | 102 | 99.5 | 11.5 | 59.2 |

| -85 | 85 | 110 | 105.5 | 13.5 | 59.2 |

| -90 | 90 | 117 | 111.5 | 13.5 | 62.2 |

| -95 | 95 | 122 | 116.5 | 13.5 | 62.2 |

| -100 | 100 | 127 | 119.5 | 13.5 | 75.2 |

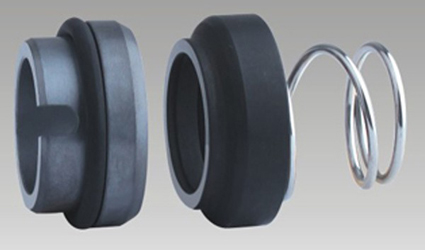

NM2N MECHANICAL SEAL