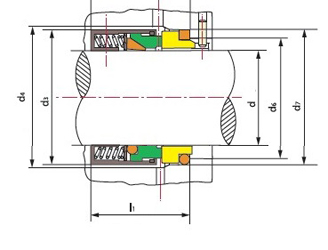

| NMSUO/W SEALS By SIZE | d | D | D1 | L1 | L2 |

|---|---|---|---|---|---|

| -14 | 14 | 24 | 25 | 12 | 23.2 |

| -16 | 16 | 26 | 27 | 12 | 23.2 |

| -18 | 18 | 32 | 33 | 13.5 | 24.2 |

| -20 | 20 | 34 | 35 | 13.5 | 24.2 |

| -22 | 22 | 36 | 37 | 13.5 | 24.2 |

| -24 | 24 | 38 | 39 | 13.5 | 26.9 |

| -25 | 25 | 39 | 40 | 13 | 27.2 |

| -28 | 28 | 42 | 43 | 12.5 | 30.2 |

| -30 | 30 | 44 | 45 | 12 | 30.7 |

| -32 | 32 | 46 | 48 | 12 | 30.7 |

| -33 | 33 | 47 | 48 | 12 | 30.7 |

| -35 | 35 | 49 | 50 | 12 | 30.7 |

| -38 | 38 | 54 | 56 | 13 | 32.2 |

| -40 | 40 | 56 | 58 | 13 | 32.2 |

| -43 | 43 | 59 | 61 | 13 | 32.2 |

| -45 | 45 | 61 | 63 | 13 | 32.2 |

| -48 | 48 | 64 | 66 | 13 | 32.2 |

| -50 | 50 | 66 | 70 | 13.5 | 34.2 |

| -53 | 53 | 69 | 73 | 13.5 | 34.2 |

| -55 | 55 | 71 | 75 | 13.5 | 34.2 |

| -58 | 58 | 78 | 78 | 13.5 | 39.2 |

| -60 | 60 | 80 | 80 | 13.5 | 39.2 |

| -63 | 63 | 83 | 83 | 13.5 | 39.2 |

| -65 | 65 | 85 | 85 | 13.5 | 39.2 |

| -68 | 68 | 88 | 90 | 13.5 | 39.2 |

| -70 | 70 | 90 | 92 | 14.5 | 45.7 |

| -75 | 75 | 95 | 97 | 14.5 | 45.7 |

| -80 | 80 | 104 | 105 | 15 | 45.2 |

| -85 | 85 | 109 | 110 | 15 | 45.2 |

| -90 | 90 | 114 | 115 | 15 | 50.2 |

| -95 | 95 | 119 | 120 | 15 | 50.2 |

| -100 | 100 | 124 | 125 | 15 | 50.2 |

NMSUO/W MECHANICAL SEAL