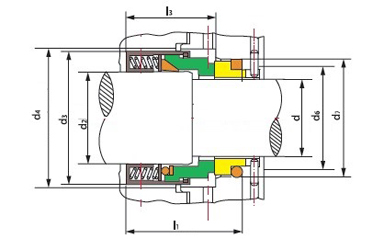

| NMSBO/W Seal size IN(MM) | d2 | d3 | d4 | I1K | I2 | I3 | d6 | d7 |

|---|---|---|---|---|---|---|---|---|

| 14 | 18 | 32 | 34 | 42.5 | 18 | 30.5 | 21 | 25 |

| 16 | 20 | 34 | 36 | 42.5 | 18 | 30.5 | 23 | 27 |

| 18 | 22 | 36 | 38 | 45.0 | 20 | 31.5 | 27 | 33 |

| 20 | 24 | 38 | 40 | 45.0 | 20 | 31.5 | 29 | 35 |

| 22 | 26 | 40 | 42 | 45.0 | 20 | 31.5 | 31 | 37 |

| 24 | 28 | 42 | 44 | 47.5 | 20 | 34.2 | 33 | 39 |

| 25 | 30 | 44 | 46 | 47.5 | 20 | 34.5 | 34 | 40 |

| 28 | 33 | 47 | 49 | 50.0 | 20< | 37.5 | 37 | 43 |

| 30 | 35 | 49 | 51 | 50.0 | 20 | 38.0 | 39 | 45 |

| 32 | 38 | 54 | 58 | 50.0 | 20 | 38.0 | 42 | 48 |

| 33 | 38 | 54 | 58 | 50.0 | 20 | 38.0 | 42 | 48 |

| 35 | 40 | 56 | 60 | 50.0 | 20 | 38.0 | 44 | 50 |

| 38 | 43 | 59 | 63 | 52.5 | 23 | 39.5 | 49 | 56 |

| 40 | 45 | 61 | 65 | 52.5 | 23 | 39.5 | 51 | 58 |

| 43 | 48 | 64 | 68 | 52.5 | 23 | 39.5 | 54 | 61 |

| 45 | 50 | 66 | 70 | 52.5 | 23 | 39.5 | 56 | 63 |

| 48 | 53 | 69 | 73 | 52.5 | 25 | 39.5 | 59 | 66 |

| 50 | 55 | 71 | 75 | 57.5 | 25 | 44.0 | 62 | 70 |

| 53 | 58 | 78 | 83 | 57.5 | 25 | 44.0 | 65 | 73 |

| 55 | 60 | 80 | 85 | 57.5 | 25 | 44.0 | 67 | 75 |

| 58 | 63 | 83 | 88 | 62.5 | 25 | 49.0 | 70 | 78 |

| 60 | 65 | 85 | 90 | 62.5 | 25 | 49.0 | 72 | 80 |

| 63 | 68 | 88 | 93 | 62.5 | 25 | 49.0 | 75 | 83 |

| 65 | 70 | 90 | 95 | 62.5 | 25 | 49.0 | 77 | 85 |

| 70 | 75 | 95 | 104 | 70.0 | 28 | 55.5 | 83 | 92 |

| 75 | 80 | 104 | 109 | 70.0 | 28 | 55.5 | 88 | 97 |

| 80 | 85 | 109 | 114 | 70. | 28 | 55.0 | 95 | 105 |

| 85 | 90 | 114 | 119 | 75.0 | 28 | 60.0 | 100 | 110 |

| 90 | 95 | 119 | 124 | 75.0 | 28 | 60.0 | 105 | 115 |

| 95 | 100 | 124 | 129 | 75.0 | 28 | 60.0 | 110 | 120 |

| 100 | 105 | 129 | 134 | 75.0 | 28 | 60.0 | 115 | 125 |

NMSBO/W MECHANICAL SEAL