|

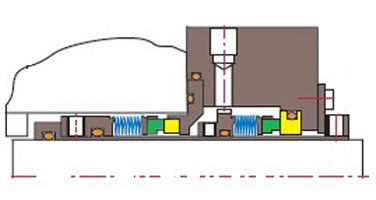

NMBD |

D |

DA |

LB |

LB |

H |

|||

|---|---|---|---|---|---|---|---|---|

|

MAX DIA |

MIN DIA |

MAX LEN |

MIN |

a |

b |

c |

||

|

1.000 |

4.130 |

1.750 |

1.880 |

2.030 |

2.060 |

2.900 |

3.630 |

3.630 |

|

1.125 |

4.250 |

1.750 |

1.880 |

2.030 |

2.060 |

2.900 |

3.630 |

3.630 |

|

1.250 |

4.250 |

2.000 |

2.130 |

2.060 |

2.130 |

3.020 |

3.630 |

3.630 |

|

1.375 |

4.250 |

2.000 |

2.190 |

2.060 |

2.030 |

3.250 |

3.630 |

3.630 |

|

1.500 |

4.500 |

2.250 |

2.380 |

2.250 |

2.130 |

3.500 |

3.630 |

3.630 |

|

1.625 |

5.000 |

2.380 |

2.500 |

2.210 |

2.130 |

3.560 |

3.690 |

3.630 |

|

1.750 |

5.500 |

2.500 |

2.560 |

2.340 |

2.130 |

3.630 |

3.750 |

3.630 |

|

1.875 |

5.500 |

2.630 |

2.690 |

2.340 |

2.130 |

3.750 |

3.880 |

3.630 |

|

2.000 |

5.500 |

2.750 |

2.940 |

2.340 |

2.130 |

4.010 |

4.130 |

3.630 |

|

2.125 |

6.000 |

3.000 |

3.190 |

2.400 |

2.130 |

4.250 |

4.380 |

4.500 |

|

2.250 |

6.250 |

3.130 |

3.190 |

2.400 |

2.130 |

4.250 |

4.380 |

4.500 |

|

2.375 |

6.250 |

3.250 |

3.440 |

2.310 |

2.250 |

4.380 |

4.500 |

4.630 |

|

2.500 |

6.500 |

3.380 |

3.440 |

2.410 |

2.190 |

4.560 |

4.810 |

4.810 |

NMBD DOUBLE METAL BELLOW CARTRIDGE SEAL