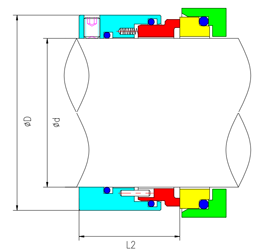

| NSOC SEALS By SIZE | D | D1 | L2 |

|---|---|---|---|

| -16 | 16 | 30.45 | 35 |

| -18 | 18 | 32.28 | 35.2 |

| -20 | 20 | 34.29 | 35.2 |

| -22 | 22 | 36.3 | 35.2 |

| -24 | 24 | 38.3 | 35.2 |

| -25 | 25 | 39.29 | 35.2 |

| -28 | 28 | 42.29 | 35.2 |

| -30 | 30 | 44.3 | 35.2 |

| -32 | 32 | 46.3 | 44.65 |

| -33 | 33 | 47.9 | 44.65 |

| -35 | 35 | 49.48 | 44.65 |

| -38 | 38 | 54.28 | 44.65 |

| -40 | 40 | 56.08 | 44.65 |

| -43 | 43 | 59.08 | 44.65 |

| -45 | 45 | 61.09 | 44.65 |

| -48 | 48 | 64.11 | 44.65 |

| -50 | 50 | 66.09 | 44.65 |

| -55 | 55 | 71.07 | 44.65 |

| -60 | 60 | 77.14 | 44.65 |

| -65 | 65 | 83.01 | 44.65 |

| -70 | 70 | 86.08 | 44.65 |

| -75 | 75 | 98.43 | 51 |

| -80 | 80 | 104.76 | 51 |

| -85 | 85 | 107.95 | 51 |

| -90 | 90 | 114.3 | 51 |

| -95 | 95 | 117.48 | 51 |

| -100 | 100 | 123.83 | 51 |

| -110 | 110 | 133.35 | 51 |

| -120 | 120 | 152.4 | 92.1 |

| -125 | 125 | 158.75 | 92.1 |

| -130 | 130 | 165.1 | 92.1 |

| -135 | 135 | 171.45 | 92.1 |

| -140 | 140 | 171.45 | 92.1 |

| -145 | 145 | 177.8 | 92.1 |

| -150 | 150 | 184.15 | 92.1 |

| -155 | 155 | 190.5 | 92.1 |

| -160 | 160 | 196.85 | 92.1 |

| -165 | 165 | 196.85 | 92.1 |

| -170 | 170 | 203.2 | 92.1 |

| -175 | 175 | 209.55 | 92.1 |

| -180 | 180 | 215.9 | 92.1 |

| -185 | 185 | 215.9 | 92.1 |

| -190 | 190 | 222.25 | 92.1 |

| -195 | 195 | 228.6 | 92.1 |

| -200 | 200 | 234.95 | 92.1 |

NSOC MECHANICAL SEAL