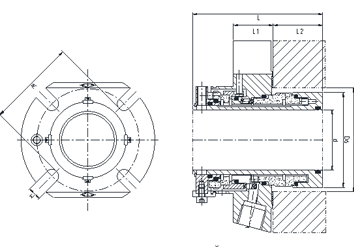

| NCART DOUBLE SEAL | d | D | D1 | L1 | L2 | L3 | C | E |

|---|---|---|---|---|---|---|---|---|

| -25 | 25 | 43 | 105 | 53.4 | 33.1 | 25.4 | 62 | 13.2 |

| -28 | 28 | 46 | 105 | 53.4 | 33.1 | 25.4 | 62 | 13.2 |

| -30 | 30 | 48 | 105 | 53.4 | 33.1 | 25.4 | 65 | 13.2 |

| -32 | 32 | 49.8 | 108 | 53.4 | 33.1 | 25.4 | 67 | 13.2 |

| -33 | 33 | 49.8 | 108 | 53.4 | 33.1 | 25.4 | 67 | 13.2 |

| -35 | 35 | 53 | 113 | 53.4 | 33.1 | 25.4 | 70 | 13.2 |

| -38 | 38 | 56 | 123 | 53.4 | 33.1 | 25.4 | 75 | 14.2 |

| -40 | 40 | 58 | 123 | 53.4 | 33.1 | 25.4 | 75 | 14.2 |

| -42 | 42 | 60.5 | 133 | 53.4 | 33.1 | 25.4 | 80 | 14.2 |

| -43 | 43 | 60.5 | 133 | 53.4 | 33.1 | 25.4 | 80 | 14.2 |

| -45 | 45 | 62.5 | 138 | 53.4 | 33.1 | 25.4 | 81 | 14.2 |

| -48 | 48 | 65.6 | 138 | 53.4 | 33.1 | 25.4 | 84 | 14.2 |

| -50 | 50 | 68 | 148 | 53.4 | 33.1 | 25.4 | 87 | 14.2 |

| -53 | 53 | 72 | 148 | 53.4 | 33.1 | 25.4 | 97 | 18 |

| -55 | 55 | 73 | 148 | 53.4 | 33.1 | 25.4 | 90 | 18 |

| -60 | 60 | 78 | 157 | 53.4 | 33.1 | 25.4 | 102 | 18 |

| -65 | 65 | 84.8 | 163 | 53.4 | 33.1 | 25.4 | 109 | 18 |

| -70 | 70 | 93 | 178 | 53.4 | 33.1 | 25.4 | 118 | 18 |

| -75 | 75 | 100 | 190 | 63.9 | 44.1 | 28 | 129 | 18 |

| -80 | 80 | 106.4 | 195 | 63.9 | 44.1 | 28 | 135 | 18 |

| -85 | 85 | 109.5 | 198 | 63.9 | 44.1 | 28 | 139 | 22 |

| -90 | 90 | 115.9 | 205 | 63.9 | 44.1 | 28 | 145 | 22 |

| -95 | 95 | 119.1 | 208 | 63.9 | 44.1 | 28 | 148 | 22 |

| -100 | 100 | 125.4 | 218 | 63.9 | 44.1 | 28 | 154 | 22 |

NCART – DOUBLE CARTRIDGE SEAL